Ben Bridge Jewelers - Various Locations Nationwide

Here at Thomas Benjamin we are super excited to show off this amazing floor we created for Ben Bridge Jewelers. 8” wide, very very complex coloration, long planks (to 12’!!) and 100% Made in the U.S.A.!

KEY SPECS

Product: Custom White Oak

Dimensions: 5/8” x 8” x RL to 12’

Species: American White Oak

Grade: Rustic Grade

Texture: Brushed

Finish: UV-cured Ceramic Acrylic

Color: Extremely complex multi-color stain and chemical fume

Painted Feather Villa- Las Vegas, NV

Stunning, muted American Walnut wideplank floor in this Las Vegas villa.

KEY SPECS

Product: Custom Walnut

Dimensions: 5/8” x 7” x RL to 10’

Species: American Black Walnut

Grade: Premium Grade

Texture: Smooth

Finish: UV-cured Ceramic Acrylic

Color: Custom Color “Taupe”

Perry's Steakhouses - our 10th Perry's!!

We have long partnered with Perry’s Steakhouses on wood flooring for their wonderful restaurants, in a variety of configurations including plank and their signature 6” x 42” herringbone.

This installation, while it is not yet finished, requires it’s own post as this is our 10th Perry’s restaurant project! We are so excited to see this beautiful herringbone floor go in! More pics to come when it’s all buttoned-up.

KEY SPECS

• Product: Perry’s Signature Herringbone

• Dimensions: 5/8” x 6” x 42”

• Species: American White Oak

• Grade: Premium Grade

• Texture: Subtly Brushed

• Finish: UV-cured Ceramic Acrylic, Matte

• Color: Perry’s Signature

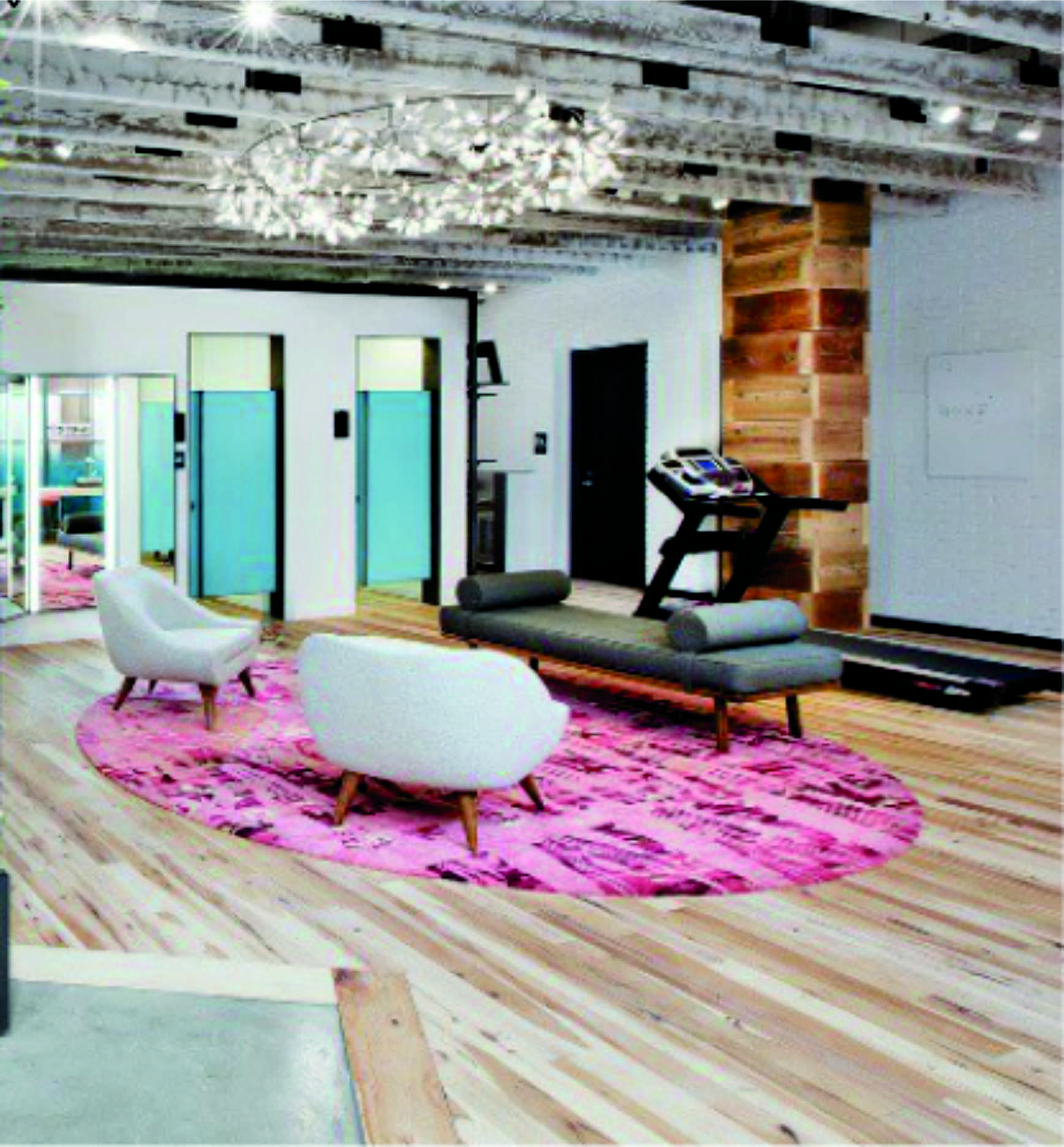

Chelsea Collective - Pittsburgh, PA and Tyson's Corner, VA

When the designers for Chelsea Collective, a women’s’ athleasure concept-store being launched by Dick’s Sporting Goods, approached us to collaborate on a “statement” floor they desired for the stores, the slate was essentially blank.

Oh, they had a wish-list: eye-catching, interesting, durable and easy to maintain.

We met in our custom sampling workroom in Southern California, and quickly narrowed things down to this beautiful calico-sorted American Hickory, in two plank widths and with an easy-maintenance low-gloss European Oil finish.

About a year after install the worth of an oil finish was demonstrated when there was a “water event” in one of the stores, that involved about as much grime and gunk as water.

Thomas Benjamin personnel flew out and consulted on the clean-up and re-oiling, all of which was accomplished in one overnight session.

KEY SPECS

Product: Custom Flooring:

Dimensions: 5/8” x 4” and 5/8” x 8” x RL to 12’

Species: American Hickory

Grade: Rustic Grade

Finish / color: European Oil Finish, Natural Color

Major Retailer

Thomas Benjamin was approached by this major nationwide fashion retailer and tasked with developing a wood floor that could stand up to the traffic and abuse a floor would take in such an environment.

We currently produce several iterations of this floor in a variety of grades, colors and finish types.

The common thread that links the floors is a degree of tactile and visual noise created by the handsculpting and liming effects that serves to camouflage minor damage and everyday grime.

To meet certain ADA requirements when connecting to adjoining surfaces, TB specially engineers this floor with a custom thickness of 7/16”

KEY SPECS

Product: Custom Product

Texture: Softly handculpted and limed per client’s request

Dimensions: 7/16” x various widths

Species: American White Oak

Grade: Select Grade

Finish: Various finishes including Ceramax UV-cured Ceramic Finish

Color - various colors developed in conjunction with client’s own in-house design staff

Nationwide Retailer: Averting Disaster

The architect for a major nationwide retailer contacted us with an urgent problem: they had specified a wood floor from another manufacturer for a high-profile installation.

Problem was, they had been told that the flooring was manufactured in Europe, and that it was available with a short lead-time of 5-6 weeks. Then, when they placed the order for the flooring, they found that it was in fact made in China and would not be available for 12 weeks or longer.

The architect, faced with losing face over delaying the project or having to switch the design for the space to utilize flooring that could be purchased off-the-shelf, called Thomas Benjamin.

The Result

Three fully custom samples.

Collaborative design for form as well as function.

All in 5 days.

From disaster, to disaster averted, That’s the TB difference!

The timeline

Monday morning, conference call

The floor was verbally described to us, as photos and samples were not available. The descriptions were a bit vague and imprecise, but there was enough to get started.

The first Custom Sample was produced and shipped out by air that day, for delivery Tuesday.

Tuesday morning conference call

The first sample was received by the architect and evaluated. Unsurprisingly, it was not exactly what was wanted, but now with a sample in-hand to discuss, conversations were more productive. Verbal course corrections were given, and expected traffic, cleaning and maintenance capabilities were discussed so that an appropriate product, with a suitable texture and finish, could be designed.

Custom Sample #2 was created and shipped out that day.

Wednesday morning conference call

The second sample was received and discussed. TB management suggested an increased level of hand texturing, as this creates an elevated level of visual noise within the product which serves to hide the occasional bit of dirt and grime, and to disguise the inevitable minor damage that would occur in such a high-traffic environment.

These suggestions were accepted, and Custom Sample #3 was shipped out.

Thursday afternoon conference call

Architect was pleased with Custom Sample #3 and sent it to the client for approval.

Friday afternoon conference call

Sample #3 was approved by the client’s Store Design department, with a minor change: due to ADA requirements, maximum slope from the new floor to an existing floor dictated a maximum wood floor thickness of 7/16”, a non-standard dimension. TB production personnel were consulted, and it was agreed that this was feasible, and no additional sample was required. Dimension drawings were made and sent for approval, along with price quotes and a lead-time of 6 weeks (for 10,000 sq ft of 100% custom manufactured flooring).

And now, 8 years later?

Over 1,000,000 square feet of this floor, and subsequent design iterations, installed for this client.

Palomar Hotel - Beverly Hills, CA

Custom band-saw marked white oak on walls, ceilings and floors. Walls and ceilings are Class A fire-rated.

Thanks to Spectra Contract Flooring for working with us on this project!

KEY SPECS

Product: TB Custom White Oak floors, walls, ceilings

Dimensions: 5/8” x 4” x RL to 12’

Species: American White Oak

Grade: Premium Grade

Texture: Custom Texture - Band Sawn

Finish: Rubio European Oil FInish

Color: Custom Color “Palomar Hotel”

Special: Walls and Ceilings Fire-rated to meet ASTM E84 Class A / I

Major Retailer - Grey Lyed Oak

Stunning lye-treated and frosted hand-distressed Premium White Oak for a Major Nationwide Fashion Retailer.

KEY SPECS

Product: Custom Flooring

Dimensions: 7/16” x 6” x RL to 12’

Species: American White Oak

Grade: Premium Grade

Texture: Custom Handsculpted

Finish: UV-cured Ceramic Acrylic, Matte

Color: Extremely complex custom finish developed in coordination with the client’s in-house design staff and architect

Microsoft Access Floor

Thomas Benjamin Architectural Flooring is a rather unique wood flooring company. Large enough to have the manufacturing capability to produce nearly any size job, yet responsive and connected enough to be able to adapt, create and execute your project, even if it doesn’t fit neatly into a predetermined “box”. Our experience creating the Access Floor for the Microsoft Visitor Center is a perfect example.

The architect contacted us on behalf of Microsoft. The MS Visitor Center in Redmond, WA was being remodeled, and the decision had been made to install wood flooring to coordinate with existing flooring in an adjacent space.

The challenge was that 70% of the new floor needed to be installed as an “Access Floor”. An Access Floor is a raised floor that provides an elevated structural floor above a solid substrate (often a concrete slab) to create a hidden void for the passage of mechanical and electrical services. This is not commonly done with wood, as the tolerances are quite tight and all of the panels, which must be removable, have to fit nearly perfectly.

We partnered with the flooring contractor in Seattle, and together we figured out how to make it work. TB personnel spent several days in Seattle working with the contractor, developing the application and fitting process for applying the wood to the access panels, and refining the specification. Then the project was handed over to the TB factory, who was tasked with precision manufacturing the wood components, which were hand-distressed and custom-finished. The focus then passed back to the contractor, who adhered the wood to the panels and fitted them into place, along with crafting a rather tricky ramp area.

What’s more, this was all accomplished in a period of less than six weeks in order to meet the Visitor Center opening schedule.

This was not an easy project, but the results speak for themselves!

RESPONSIVE DESIGN - MANUFACTURING CAPABILITIES - DEPENDABLY AMERICAN MADE

Art and Soul Restaurant - Washington, DC

This client had previously used this color/texture/finish on a hotel project, and this time they tasked us with creating the same thing in a herringbone for the Art & Soul Restaurant on Capitol Hill.

KEY SPECS

Product: Custom White Oak Herringbone

Dimensions: 5/8” x 4” x 24”

Species: American White Oak

Grade: Premium Grade

Texture: Subtly Brushed

Finish: UV-cured Ceramic Acrylic, Matte

Color: Custom Color “Espresso”

Colonial Country Club - Fort Worth, TX

What do you do when a designer falls in love with a floor in a photo, which happens to be in a 300-year-old Scottish hunting lodge, and wants that floor re-made for one of the most prestigious country clubs in the country?

You get to work!

We custom-built, handsculpted, finished and pre-assembled this floor in only 6 weeks, and it looks fantastic!

The floor in the original photo was a Scottish Oak basketweave floor. (see photo)

The designers decided they would prefer to switch to Hickory for the added hardness and beautiful color variation inherent in this species.

KEY SPECS

Product: Custom - Custom - Custom!

Dimensions: 3/4” engineered x 42” x 42” Beaketweave Pattern

Species: American Hickory

Grade: Light

Texture: Subtly Brushed

Finish: UV-cured Ceramic Acrylic, Matte

Color: Custom Color “Amaretto”