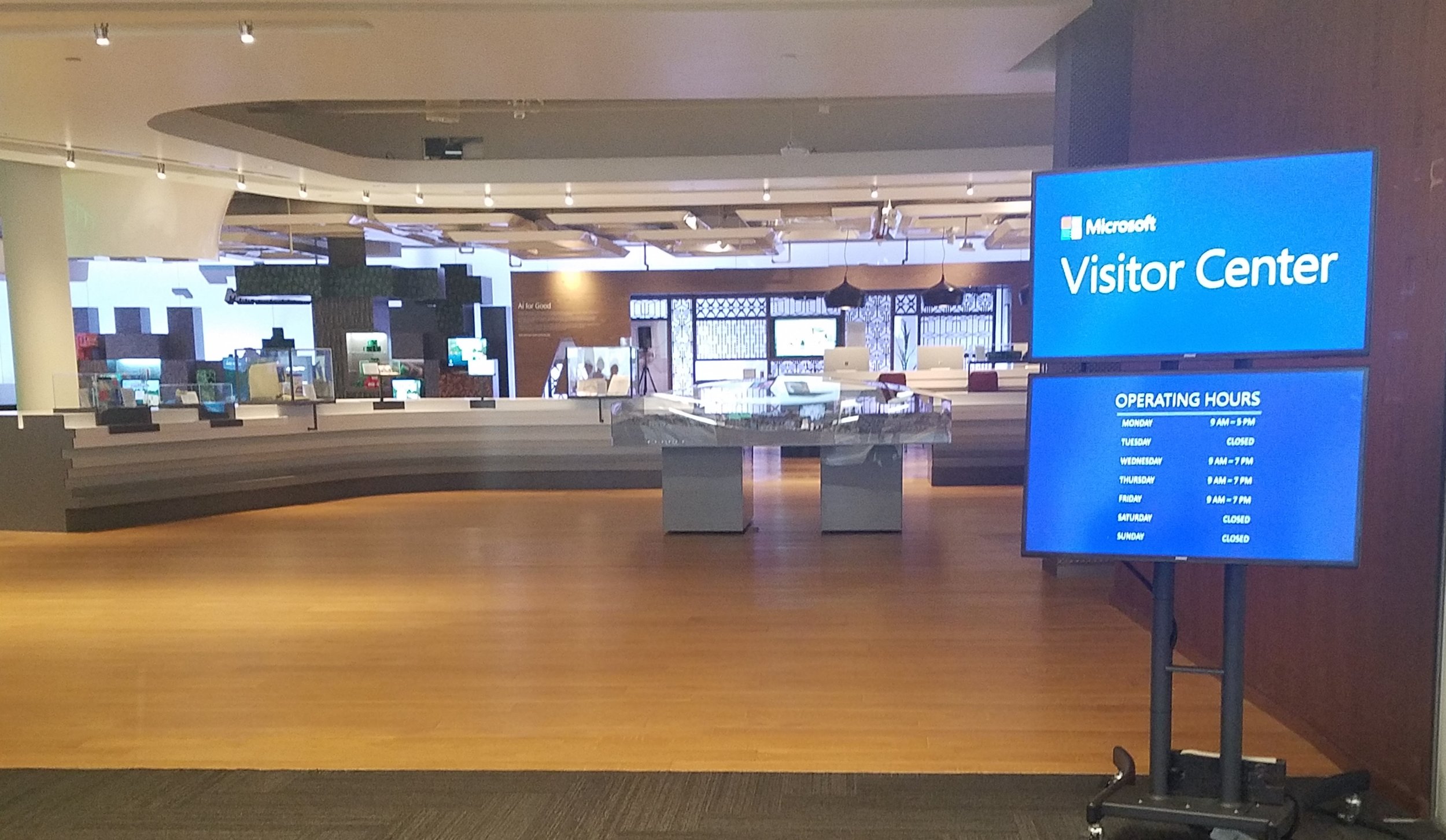

Thomas Benjamin Architectural Flooring is a rather unique wood flooring company. Large enough to have the manufacturing capability to produce nearly any size job, yet responsive and connected enough to be able to adapt, create and execute your project, even if it doesn’t fit neatly into a predetermined “box”. Our experience creating the Access Floor for the Microsoft Visitor Center is a perfect example.

The architect contacted us on behalf of Microsoft. The MS Visitor Center in Redmond, WA was being remodeled, and the decision had been made to install wood flooring to coordinate with existing flooring in an adjacent space.

The challenge was that 70% of the new floor needed to be installed as an “Access Floor”. An Access Floor is a raised floor that provides an elevated structural floor above a solid substrate (often a concrete slab) to create a hidden void for the passage of mechanical and electrical services. This is not commonly done with wood, as the tolerances are quite tight and all of the panels, which must be removable, have to fit nearly perfectly.

We partnered with the flooring contractor in Seattle, and together we figured out how to make it work. TB personnel spent several days in Seattle working with the contractor, developing the application and fitting process for applying the wood to the access panels, and refining the specification. Then the project was handed over to the TB factory, who was tasked with precision manufacturing the wood components, which were hand-distressed and custom-finished. The focus then passed back to the contractor, who adhered the wood to the panels and fitted them into place, along with crafting a rather tricky ramp area.

What’s more, this was all accomplished in a period of less than six weeks in order to meet the Visitor Center opening schedule.

This was not an easy project, but the results speak for themselves!

RESPONSIVE DESIGN - MANUFACTURING CAPABILITIES - DEPENDABLY AMERICAN MADE